I have made some small updates.

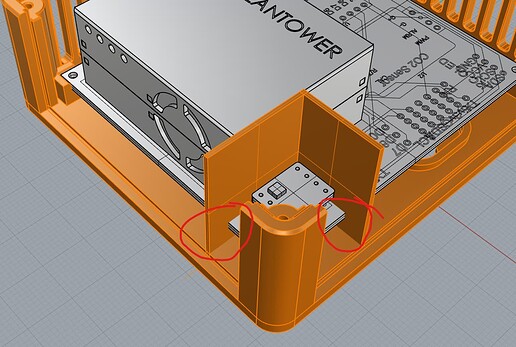

Moving the screws to the bottom is a bit more complex than expected and is still on the todo list.

It is ofcourse a matter of preference. Having the screws on top is more convinient for assembly.

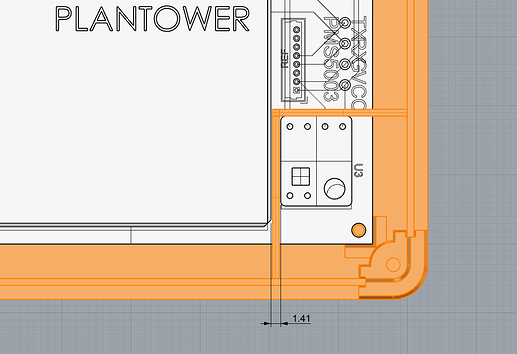

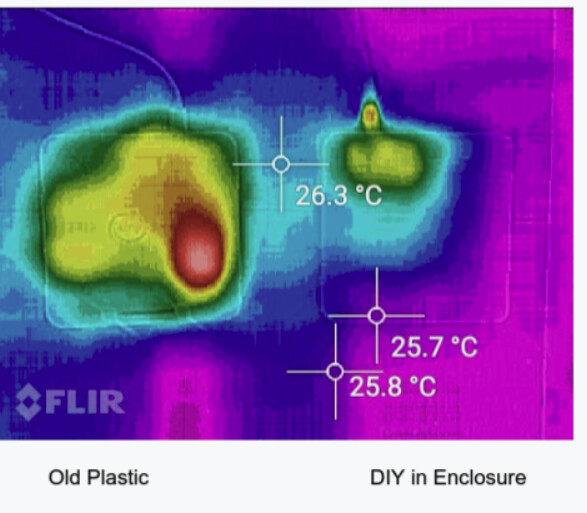

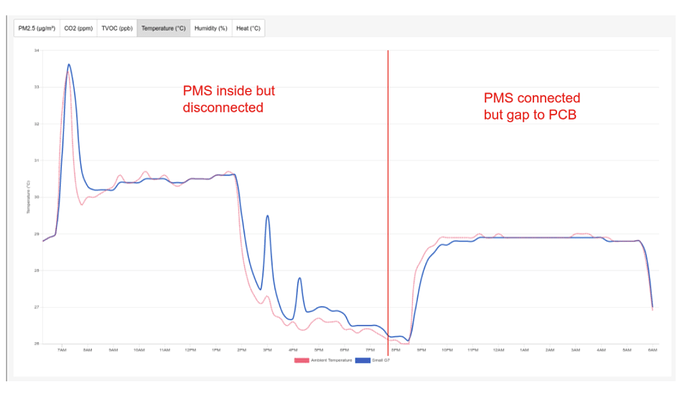

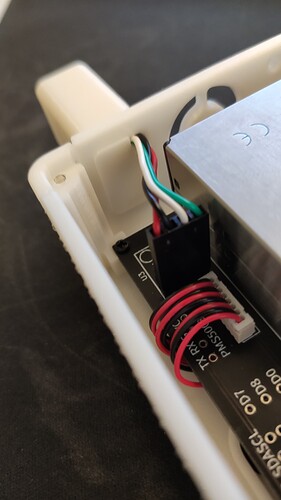

In order to compensate somewhat the “temperature leaking” I have added two new elements with a 20mm and 30mm extension for the SH3x.

I share now the folder instead of the files so that updating is more convinient.

https://drive.google.com/drive/folders/18hyBFjyJzBdfCH8klpFMiMLU_LZll0Xh?usp=sharing

BTW what works nicely is the concept of the replacable sides. I can now swap out the sides without the need to reprint the whole case.