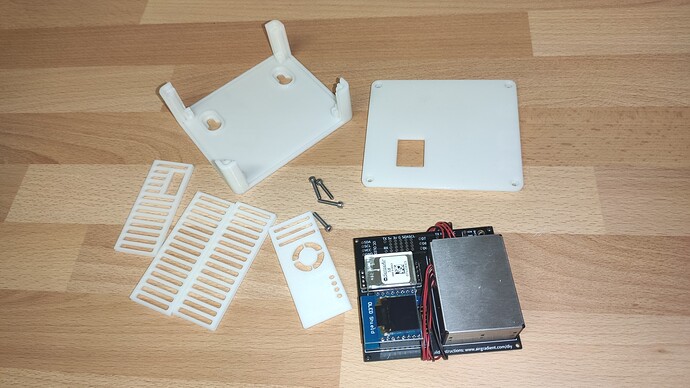

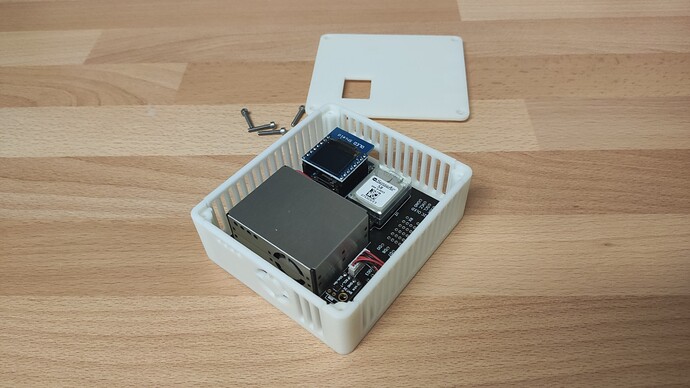

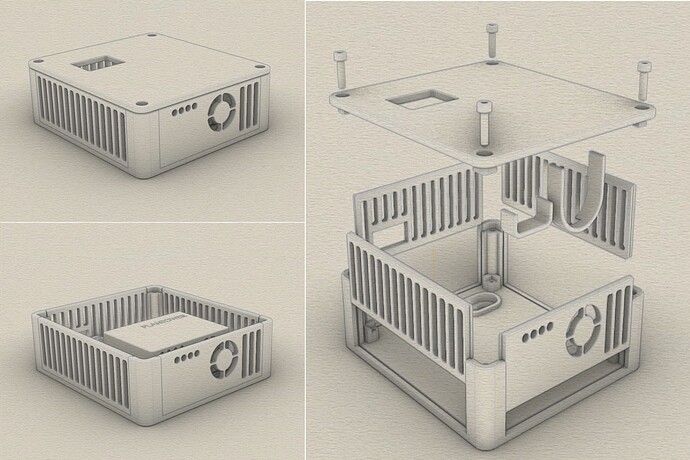

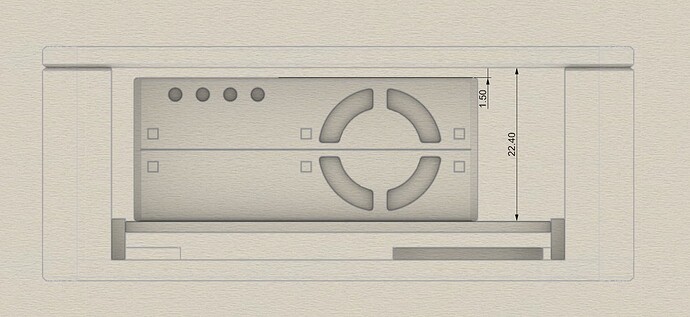

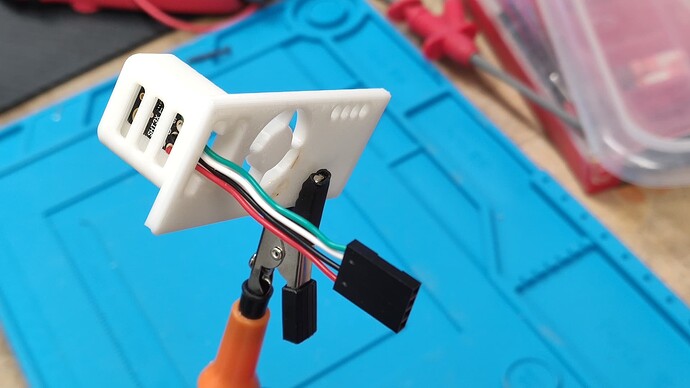

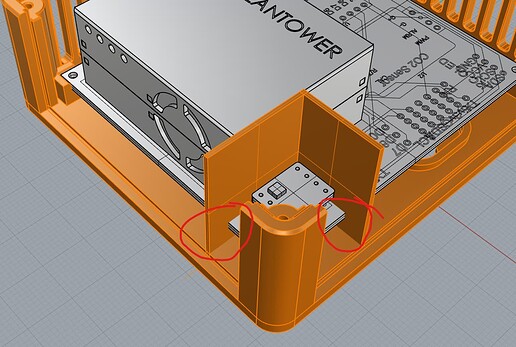

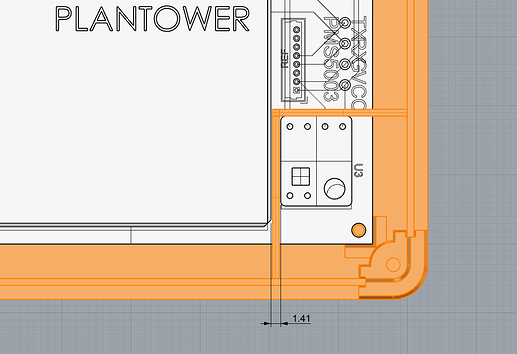

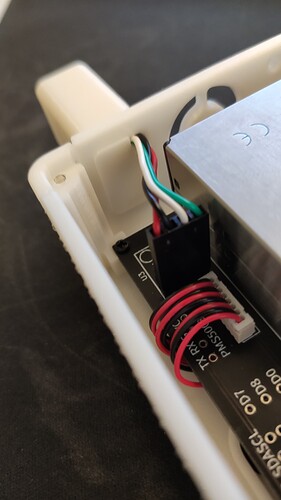

I wanted to make my own enclusore. I paid attention on printability, ventilation and flexibility. The enclosure orientation is horizontal or vertical. The side walls can be swapped out for different designs. The PCB is attached with small self tapping screws. The top with 4x M2.5x12 mm bolts (8mm would be ideal but I had 12mm in stock).

The case was printed with eSun PLA+ on my Prusa MK3 with 0,2mm layer height and no supports.

The STEP/STP file is available on my google drive.

https://drive.google.com/file/d/1R2aJRWKAr5R3vcG7h97ao5NLkBjwaHvD/view?usp=sharing

The 3MF files (I prefer 3MF instead of STL)

https://drive.google.com/file/d/1Qokz7NuxpzFrb7aSjuQmoETKw9WD1VEs/view?usp=sharing