What Are PM Sensors?

Before we dive into the details about this tiny sensor, let me quickly explain what PM sensors actually do. PM stands for particulate matter, which are the tiny particles floating around in the air that we can’t see with our naked eyes. These sensors measure concentrations of particles like PM2.5 (particles smaller than 2.5 micrometers) and PM10 (particles smaller than 10 micrometers), which include things like dust, pollen, smoke, and other pollutants. Many consumer air quality monitors use these sensors to tell you whether the air you’re breathing is clean or if you are breathing unhealthy air.

Why Is Bosch Making Waves?

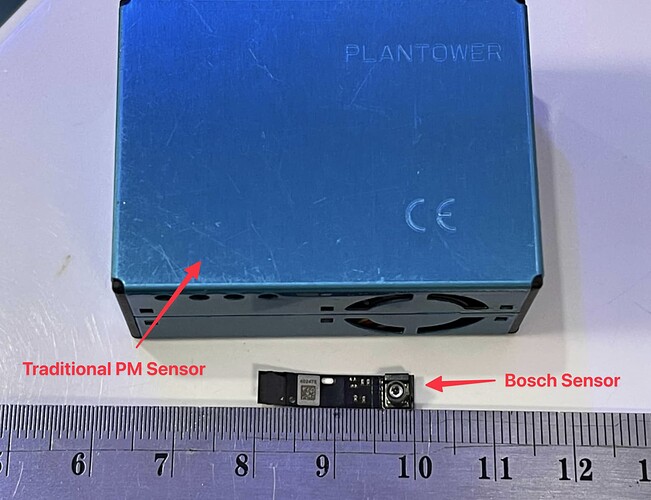

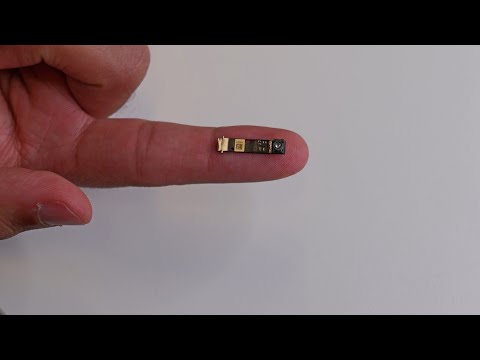

Bosch recently released a PM sensor that caused a bit of a stir within the industry. When you see the size of the sensor, it’s easy to understand why! Coming in at only 4.4mm x 3mm x 20mm, the BMV080 is by far the smallest PM sensor we’ve seen to date. Just look at the image below which shows the size difference between the BMV080 and a Plantower PMS5003 (which our monitors use).

This begs the question - how does it actually perform?

This is a question we’ve received quite a few times in the past weeks, and honestly, we were curious ourselves. So we decided to investigate. A big thank you to our engineer, Xin, for helping conduct all of these tests!

What Makes This Sensor So Different

There are a few things that make the BMV080 unique beyond its tiny size. Most obviously, that miniature form factor means it could work in applications where traditional PM sensors simply won’t fit.

To achieve this smaller size, Bosch had to completely rethink how current particle sensors work. Where most consumer-grade PM sensors use a laser and photodiode setup to measure particles within an enclosed chamber, the BMV080 takes a different approach. It uses integrated lasers with tiny diodes built in and instead of firing a laser across an internal chamber (which requires a minimum distance between components), the BMV080 aims its laser outwards and measures particles in the surrounding air by measuring how much light is reflected back towards the sensor.

This means the sensor is actually measuring particles in a zone up to 35cm in front of the device, not particles inside the chamber (like most current PM sensors).

This approach also eliminates the need for a fan to ensure consistent airflow. While we can’t speak to the longevity yet (we simply haven’t had it long enough), Bosch claims this design prevents dust buildup, potentially giving the sensor a longer lifespan than traditional designs.

Our Observations

Before conducting formal accuracy testing against our reference monitor and Plantower sensors, we wanted to understand what this revolutionary new form factor actually means in practice. The BMV080’s unique design creates entirely different benefits and limitations compared to traditional PM sensors.

Our focus for this round of testing was specifically on form factor implications. How does this external measurement approach behave in real-world conditions? What new possibilities does it create, and what constraints does it impose?

We’re planning more testing against our reference monitor soon, but to start, we wanted to test the sensor in various real-world situations. Some results were expected, but a few surprised us.

Note: In the test footage, the sensor is attached to our development/testing board, so it looks bulkier than the actual device. You can see how tiny the sensor itself is in the image above.

Initial Impression: From our preliminary testing, it appears to be measuring PM2.5 with similar values to the Plantower sensors and AirGradient monitors we compared it to. However, we haven’t yet had a chance to properly compare it, and this is something we intend to do in the coming weeks.

Warm-Up Time

Every time we turned the sensor on, we noticed a considerable delay before it would start reporting accurately. When first powered up, the readings would spike dramatically, taking 45-60 seconds to normalize. For context, Plantower sensors also need about 20 seconds to warm up, but the BMV080’s warm-up period is significantly longer with a much more dramatic spike.

This won’t be an issue if the sensor can stay constantly powered, but it makes the device less ideal for applications requiring frequent on/off cycles. Current portable devices using sensors like the Plantower or Sensirion SPS30 only turn on intermittently to save battery life. Since the BMV080 likely uses far less power (something we still need to test), it might actually be able to stay on continuously in situations where other sensors would cycle on and off negating this downside. Of course, for static monitors that have a continuous power supply, this won’t be an issue.

Obstructions

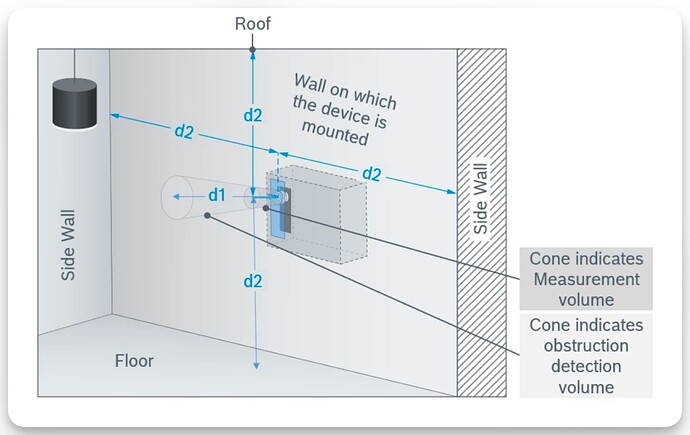

Unlike traditional PM sensors that contain both laser and detector within a single chamber, the BMV080 fires its laser into open air. This creates an obvious limitation - you need a clear line of sight for at least 35cm in front of the sensor (Bosch’s recommendation).

Image from BMV080 Integration Manual.

We found their 35cm estimate to be pretty accurate. If anything large passes through that space (such as a hand) the readings skyrocket immediately.

Bosch does provide an “obstruction detection” mode, but it has limited usefulness. Instead of alerting us to obstructions, it just kept repeating the last reading from before the obstruction was detected. So if the sensor measured 9 µg/m³ of PM2.5 and then detected an obstruction, it would continue showing 9 µg/m³ until the obstruction cleared.

Shock and Vibrations

Since this sensor could be excellent for portable applications, we tested how it handles movement. The results were surprisingly good - consistent readings even while the sensor was being shaken around in the air.

However, when we flicked the device hard (simulating significant vibrations), readings shot up immediately and took over 30 seconds to normalize. While flicking a sensor is pretty extreme, this suggests the device might struggle with serious vibrations. We’ll need to test this more thoroughly.

While this might seem like quite an unlikely situation, we wanted to do this test because the BMV080 could be the ideal PM sensor for portable monitors. However, as someone who usually has an Atmotube attached to my backpack, I can say that it certainly gets exposed to quite a few bumps throughout the day.

Bright Light

Since the device emits a laser outward, we wondered if direct bright light - like sunlight - would interfere with readings. We shone a bright light directly at the sensor, and it performed well. The sensor should provide accurate readings even in bright conditions.

We checked Bosch’s documentation to see if a light wavelength was mentioned, but we were unable to find any further information.

High Temperatures

We used a hair dryer to heat the device while monitoring PM readings. The AirGradient monitor in the background (about 30cm away) recorded a 5°C increase, but the Bosch sensor likely reached much higher (and quite extreme) temperatures.

Even with this temperature increase, the BMV080 recorded virtually no change in particle concentration. Any minor changes we saw were probably from particles blown past the sensor by the hair dryer, not temperature effects.

Looking at Bosch’s specifications this makes sense. They state that temperature changes don’t affect precision (consistency), but that accuracy can degrade at temperatures away from the 25°C calibration point that these sensors are tested at. As per their documentation, at 35°C, additional measurement errors of around ±11 µg/m³ are expected, which our simple test setup wouldn’t have detected. This is something we will have to test against our reference monitor.

Rain Simulation

The sensor isn’t waterproof, so we didn’t put it in water. But we were curious whether water falling in front of the sensor (within that 35cm detection zone) would affect readings. Again, this could be important if this sensor is to be used in a portable or outdoor monitor.

We simulated rain falling in front of the sensor, and it performed excellently. There was no reaction to the falling water at all.

Wind Testing

We exposed the sensor to direct wind from a handheld fan. While there were some reading changes, none were significant, and they were likely caused by particles being blown around rather than the wind itself affecting the sensor operation. The sensor maintained stable performance.

The Glass Test

For our final test, we placed a glass screen protector over the sensor to see if it could measure through the covering. This was particularly interesting because good performance here could indicate waterproof enclosures are possible with this sensor.

There was an initial spike when we placed the cover, but readings quickly stabilized afterward. While we haven’t tested the accuracy of readings through glass or clear plastic yet, the device clearly continued functioning.

This has some exciting implications for air quality monitor applications, and we’re eager to test it further against our reference sensor.

What’s Next

We’re quite excited about this sensor’s potential (as you can probably guess by all of the tests we’ve already conducted!). The size alone opens up possibilities that simply weren’t feasible before, and the measurement approach is very clever.

We’ll be conducting much more extensive testing in the coming weeks, including comparisons against our reference monitor and head-to-head tests with the Plantower sensors we typically use in our monitors.

We’ve also designed our own testing PCB for these evaluations. Once we’re confident it works reliably, we plan to open-source the design for anyone else interested in experimenting with this sensor.

If you want to learn more about the BMV080, check out Bosch’s official sensor page for technical specifications.

If you have questions about our testing or suggestions for future evaluations we’d love to hear from you!