I just purchased my Air Gradient DIY Pro. The hardware itself is excellent and the assembly instructions were great.

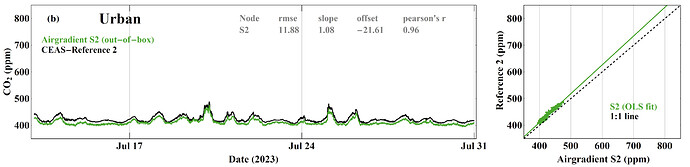

But it appears there is a combination of software problems that make the CO2 sensor not actually work indoors.

-

By default, the sensor does an “Automatic Baseline Calibration” (ABC) every “7-14 days” by taking the lowest reading it has seen and assumes that is the baseline, which will not be accurate for many homes.

If you do not open all of your doors/windows every 7-14 days, the sensor will ABC wrong and the readings will not be accurate.

The devs say that “In more then 95% of the indoor rooms we monitor we see ambient levels at least once a week.”

But several users have explained that this is not true for many homes. -

The first recommended fix for inaccurate readings is to “just wait a week or two for it to calibrate”, but this this will not work because of #1. In fact, it will get more wrong every week.

-

The second recommended fix is manually calibrate your device via some arduino code, but this will not work because the flashing instructions have a bug and currently flash the wrong firmware version and your device will bootloop. The fix is a simple git error but has not been updated since the last release in April 2023.

-

The third recommended fix is to do one calibration and then disable the ABC. This has been discussed since November 2022 and it is known the sensor itself supports disabling the ABC, there is no code available to do this.

-

It seems there is a way to trigger a manual calibration remotely for the commercial version of the device (which to my understanding is identical to the DIY). This can been seen on the dashboard, but is not available to DIY users.