I bought my sensors and ESP controller separately before they were available as a kit however shortly after that, kits were made available for purchase directly from AirGradient and thus decided for the time being to order a PCB since it was a lot cheaper than having it manufactured locally.

Unfortunately, shipping has been very slow so far with a couple of big gaps between updates. At the time of writing the package has been in transit for 37 days with the last update on the 8th of November and while I hope it’ll still arrive , I made peace with the idea that the package could have been lost in transit.

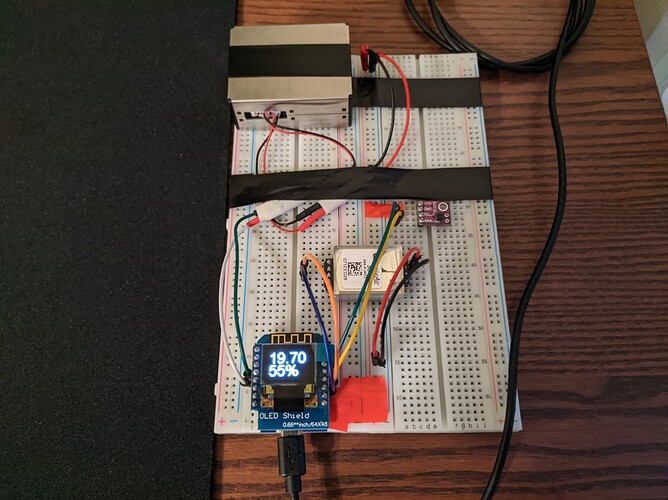

If anyone wonders, this is how I’ve been using it over the last couple of weeks  :

:

My plan was that once it arrives, I’ll move all the components from the breadboard over to the PCB and print the enclosure for it at a local shop. That being said, since it doesn’t look like this’ll work out, I’ve been thinking of alternatives.

One of the things that I’ve been wondering about is whether there is a strong case to even use a PCB. Since the connections between the components aren’t complicated, would there be any downside in making an enclosure in which the sensors/controller/lcd can be “slotted” in and connected through wires directly?

I don’t have any “real experience” with 3D printing/CAD modeling so I don’t know if there are any downsides to this approach. Do you have any thoughts on it?