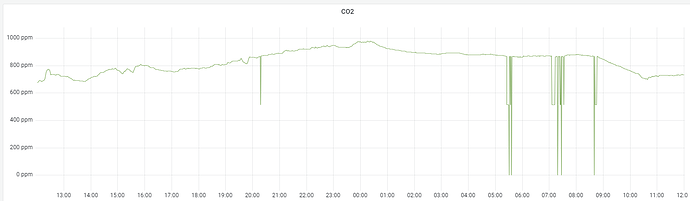

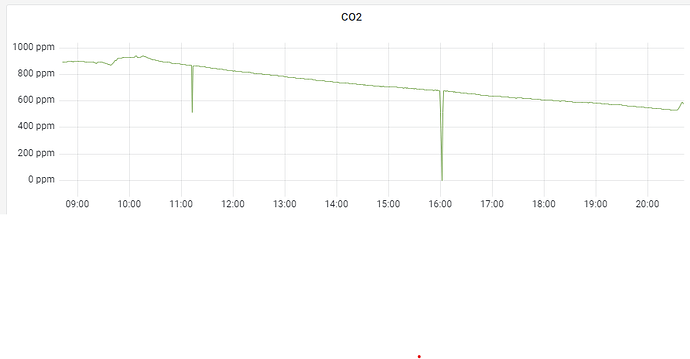

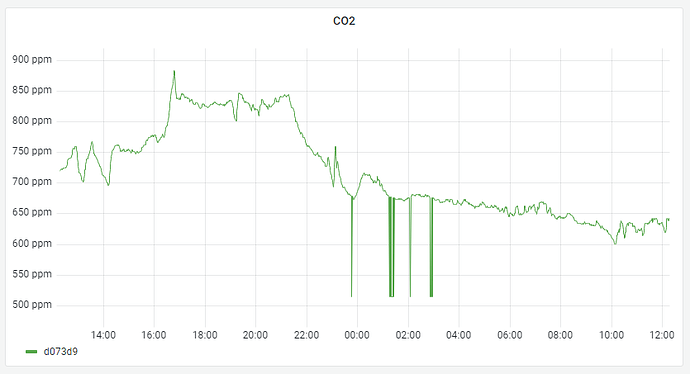

So I have a recently-built sensor, where the CO2 module sometimes reports 0, or strangely-low values (like 520ppm when the surrounding ones are >800ppm). Here’s a graph:

Is this just normal sensor noise? Or is there something wrong with the connection between the sensor and the PCB? I could resolder those.

I can of course paper over these values by doing quantiles/median when graphing, or ignoring all zero values, but a) that is just papering over it and b) would not solve the too-low-but-not-0 values.

I’ll keep it running as is to get more data.

I’ll keep it running as is to get more data.