I have 3 of these setup now and have not been able to read anything but -2 from the s8 as of yet.

I am using CO2_Simple sample code

Here are some of my tries:

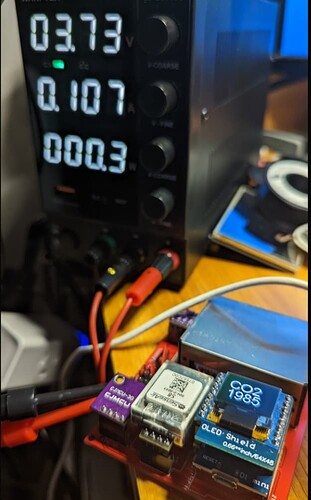

- Ensure good stable 5V supply - I do see a small led flash in the sensor roughly every 3-5 seconds

- Tried changing code delays/timeouts

- Checked soldering

- Breadboarded circuit so same as AirGradient pcb

- Tried using different D1 mini’s

- Tried several different SoftwareSerial libraries.

- Tried building/testing with Arduino IDE.

I do use PlatformIO to build using VSCode.

Blink app works fine

Only thing that I cant seem to verify is that SoftwareSerial is working correctly, and I have a feeling that is the problem. PlatformIO seems to default to EspSoftwareSerial @ 6.12.7 is this the best one?

Here is a log:

Processing d1 (platform: espressif8266; board: d1; framework: arduino)

--------------------------------------------------------------------------------------------Verbose mode can be enabled via `-v, --verbose` option

CONFIGURATION: https://docs.platformio.org/page/boards/espressif8266/d1.html

PLATFORM: Espressif 8266 (4.0.1) > WEMOS D1 R1

HARDWARE: ESP8266 80MHz, 80KB RAM, 4MB Flash

PACKAGES:

- framework-arduinoespressif8266 @ 3.30002.0 (3.0.2)

- tool-esptool @ 1.413.0 (4.13)

- tool-esptoolpy @ 1.30000.201119 (3.0.0)

- tool-mklittlefs @ 1.203.210628 (2.3)

- tool-mkspiffs @ 1.200.0 (2.0)

- toolchain-xtensa @ 2.100300.210717 (10.3.0)

LDF: Library Dependency Finder -> https://bit.ly/configure-pio-ldf

LDF Modes: Finder ~ chain, Compatibility ~ soft

Found 36 compatible libraries

Scanning dependencies...

Dependency Graph

|-- AirGradient Air Quality Sensor @ 1.5.0

| |-- EspSoftwareSerial @ 6.12.7

| |-- Wire @ 1.0

Building in release mode

Retrieving maximum program size .pio\build\d1\firmware.elf

Checking size .pio\build\d1\firmware.elf

Advanced Memory Usage is available via "PlatformIO Home > Project Inspect"

RAM: [==== ] 35.6% (used 29156 bytes from 81920 bytes)

Flash: [=== ] 26.2% (used 273741 bytes from 1044464 bytes)

Configuring upload protocol...

AVAILABLE: espota, esptool

CURRENT: upload_protocol = esptool

Looking for upload port...

Auto-detected: COM3

Uploading .pio\build\d1\firmware.bin

esptool.py v3.0

Serial port COM3

Connecting....

Chip is ESP8266EX

Features: WiFi

Crystal is 26MHz

MAC: 40:91:51:53:16:7a

Uploading stub...

Running stub...

Stub running...

Configuring flash size...

Compressed 277888 bytes to 203583...

Writing at 0x00000000... (7 %)

Writing at 0x00004000... (15 %)

Writing at 0x00008000... (23 %)

Writing at 0x0000c000... (30 %)

Writing at 0x00010000... (38 %)

Writing at 0x00014000... (46 %)

Writing at 0x00018000... (53 %)

Writing at 0x0001c000... (61 %)

Writing at 0x00020000... (69 %)

Writing at 0x00024000... (76 %)

Writing at 0x00028000... (84 %)

Writing at 0x0002c000... (92 %)

Writing at 0x00030000... (100 %)

Wrote 277888 bytes (203583 compressed) at 0x00000000 in 18.0 seconds (effective 123.8 kbit/s)...

Hash of data verified.

Leaving...

Hard resetting via RTS pin...

=============================== [SUCCESS] Took 22.01 seconds ===============================

19:27:19.980 > ₆₅₅₃₃ ₆₅₅₃₃ ₆₅₅₃₃ CO2 Successfully Initialized. Heating up for 10s

19:27:30.291 > C02: -2

19:27:35.506 > C02: -2

19:27:40.721 > C02: -2

19:27:45.936 > C02: -2

19:27:51.150 > C02: -2

19:27:56.366 > C02: -2

19:28:01.581 > C02: -2

19:28:06.795 > C02: -2

platformio.ini:

[env:d1]

platform = espressif8266

board = d1

framework = arduino

board_build.mcu = esp8266

Does anyone else see garbage character through the serial monitor at every startup, or just me…

Any ideas, suggestions appreciated…