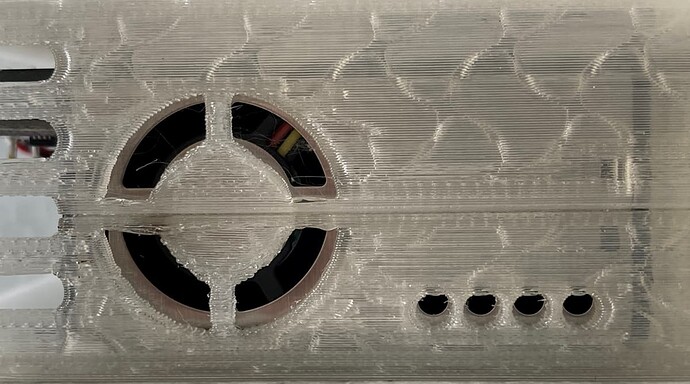

I’ve just managed to get the board mounted in the new enclosure, but it was not without a challenge.

The way I approached the assembly was to first snap the PM sensor into its guides in the lid, as that was a firm fit. (Intuitively to me that seemed the first step).

That meant that the PCB then ‘floated’ on top of it until you can bring the base close enough for its tiny pins to align with the holes in the PCB. To do this I had to close the base as far as it would go, then ‘cajole’ the board into place using a tiny screwdriver poked through the ventilation holes. Once they aligned the enclosure snapped closed nicely.

So the ONE change I think would be really helpful would be to move the tiny pins that keep the PCB in position onto the “lid” not the base.

This isn't necessarily a box issue, but I'll also need to crack it open again soon and put some kind of 'spacer' between the board and the PM sensor, to make sure the sensor is pushed fully against the lid of the enclosure. The little bit of free movement it has means its ventilation and fan holes don't align 100%. (MAYBE a printed clip in the enclosure can ensure it's held snug to the lid?

All-in-all, it’s a nice, neat little enclosure so far, but as always with these things, we could be gilding this particular lily forever.

- Greig.

the case itself turned out nice but the temperature housing gave me lots of trouble with removing the support structure resulting in many of the fine structures in the top to break off. and when i tried to gently push it into the main case one of the little retaining clips snapped. it’s being hold in place by scotch tape for now.

the case itself turned out nice but the temperature housing gave me lots of trouble with removing the support structure resulting in many of the fine structures in the top to break off. and when i tried to gently push it into the main case one of the little retaining clips snapped. it’s being hold in place by scotch tape for now.